Reverse Engineering

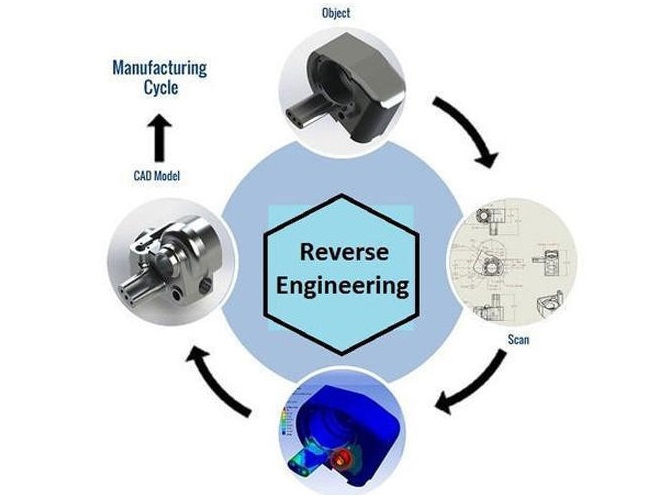

Reverse engineering involves the process of analyzing and reconstructing an existing tool, die, mold,

or mechanical component to understand its design, materials, and functionality—often with the goal

of improving, replicating, or replacing it. This process is commonly used when original design

documentation is unavailable, outdated, or incomplete. Engineers disassemble or scan a tool or

part, gather dimensional and structural data, and then use computer-aided design (CAD) software

to create a digital model that accurately reflects the original.

A key driver for reverse engineering in tooling is maintenance and legacy replacement. Many industrial

tools and molds have long life cycles, and when they wear out, replacements may no longer be

commercially available. By reverse engineering, manufacturers can reproduce these tools without

needing access to the original specifications. Additionally, reverse engineering supports innovation

and optimization, allowing engineers to analyze and enhance existing designs to improve performance,

reduce material usage, or adapt tools for new processes or materials.

Modern reverse engineering often employs technologies such as 3D scanning,

coordinate measuring machines (CMM), and CT scanning, which allow for precise digital capture of

complex geometries. The resulting data can then be processed into high-resolution CAD models and

used to manufacture new tooling via CNC machining, additive manufacturing, or other production

methods.

How MFI is transforming Reverse Engineering ?

We are a specialized engineering organization dedicated to advancing the capabilities of the tooling

industry through state-of-the-art reverse engineering solutions. With decades of combined experience

in metal forming, die making, and precision engineering, we focus on re-creating and improving

complex tooling components that are either obsolete, damaged, or require design enhancement. Our

services bridge the gap between legacy tools and modern manufacturing requirements, ensuring that

our clients remain productive and competitive in a fast-evolving industrial landscape.

At the core of Metal Form Industries' operations is the use of advanced 3D scanning, CAD modeling,

and material analysis techniques to accurately reconstruct worn or unavailable components. This

capability enables us to reverse engineer dies, molds, press tools, jigs, and fixtures with high

precision. Our expert team not only replicates original designs but also integrates improvements

to boost durability, reduce manufacturing lead times, and optimize performance in line with today’s

engineering standards.

Our reverse engineering services are particularly vital for clients in automotive,

home-appliance, consumer electronics, and heavy machinery sectors, where downtime due

to unavailable parts can result in significant losses. By offering quick turnaround

times and engineering insights, Metal Form Industries helps clients extend the

lifecycle of their equipment, reduce tooling costs, and minimize operational

disruptions. Through our relentless commitment to quality, innovation, and

technical excellence, we’ve earned a trusted reputation as a go-to partner

for tooling revitalization and optimization.

Why choose MFI for your Reverse Engineering Projects ?

Proven Excellence: We have won the confidence of our clients by offering exact solutions to a

wide range of sectors.

Cutting-Edge Technology: We remain on top of industry developments to ensure that our reverse

engineering services can manage emerging technical issues.

Cost-Effective Solutions: Our cost-effective strategy ensures that you get the most out of

your investment.

Client-Centered Approach: To bring your vision to life, we prioritize transparent

communication and cooperation.

Timely Delivery: We are devoted to meeting deadlines while maintaining high quality.