Tool Manufacturing

Tool manufacturing involves the production of specialized tools used in various manufacturing

processes, such as machining, molding, and assembly. These tools include cutting tools, molds,

dies, fixtures, and measuring instruments, each designed for a specific purpose in creating or

shaping materials like metal, plastic, or composites. Precision is a key element, as even slight

imperfections in the tools can lead to defects in the final product. The goal is to create tools

that can consistently produce high-quality, precise components for industries like automotive,

home-appliance, and electronics.

The process of tool manufacturing often requires selecting durable, wear-resistant materials such

as high-speed steel or carbide to ensure longevity and accuracy. Customization is also a significant

aspect, as tools are often tailored to the unique needs of a particular production line. For example,

custom dies are made for specific product designs, while jigs and fixtures are created to hold parts

securely during assembly or machining. Additionally, advanced technologies like CNC machining and 3D

printing are increasingly used to improve the efficiency and precision of tool production.

Maintenance and repair are essential in the tooling industry as tools wear out

over time. Reconditioning services are common to extend the life of tools and maintain their

performance. Tool manufacturing is crucial to various industries that require high-precision

parts, including automotive, aerospace, medical devices, and consumer electronics. These

industries rely on high-quality tooling to maintain production efficiency and ensure product

safety and reliability. As such, the tooling industry plays an integral role in the broader

manufacturing sector.

How MFI is revolutionizing tool Manufacturing ?

Metal Form Industries (MFI) is at the forefront of innovation in tool manufacturing, leveraging

decades of expertise to deliver high-precision tooling solutions for industries such as automotive,

aerospace, electronics, and consumer goods. With a strong focus on quality and customization, MFI

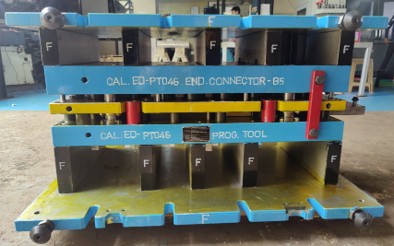

designs and manufactures a wide range of tools including Simple Tools, Compound Tools,

Progressive Tools, Transfer Tools, Automotive Press Parts, dies, jigs, and

fixtures. Our state-of-the-art facilities are equipped with advanced CNC machining centers,

EDM wire cut systems, and CAD/CAM technology, allowing us to meet the most demanding tolerances and

complex geometries required in modern production environments.

One of the key strengths of Metal Form Industries lies in its integrated approach to tool design,

manufacturing and part production. We work closely with clients from concept to completion, ensuring that each

tool is tailored to specific application needs. Our deep understanding of materials science and

process engineering allows us

to develop tooling that not only improves production output but also extends tool life and reduces

maintenance costs.

MFI is also committed to continuous improvement and technological advancement. By

incorporating real-time data monitoring, advanced material testing, and smart

automation systems into our operations, we are able to enhance productivity

and maintain consistent quality across batches. Additionally, Metal Form Industries

places a strong emphasis on sustainability by optimizing material usage and offering

reconditioning services to extend the life of existing tools. As a result, MFI

stands as a trusted partner in the tooling industry, providing innovative,

reliable, and cost-effective solutions that support manufacturers worldwide.

Why choose MFI for your Tool Manufacturing Projects ?

Proven Industry Experience

MFI brings decades of expertise in tool manufacturing, serving industries like automotive, aerospace,

electronics, and consumer products with precision-engineered solutions.

Custom Tooling Capabilities

Offers a wide range of tooling solutions including Simple Tools, Compound Tools,

Progressive Tools, Transfer Tools, Automotive Press Parts, dies, jigs, and

fixtures custom-designed to meet your specific production needs.

Advanced In-House Manufacturing

Equipped with modern CNC machining centers, EDM machines, and CAD/CAM tools, allowing full

control over quality, lead times, and project management.

Engineering Expertise

Utilizes engineering expertise to optimize tool design before production, reducing defects,

improving tool life, and minimizing costly revisions.

Customer-Centric Collaboration

Works closely with clients throughout the design and manufacturing process, ensuring tailored

solutions and open communication from start to finish.

Fast Turnaround & Quality Control

In-house processes streamline production, reduce delays, and ensure every tool meets strict

quality standards before delivery.

Cost-Efficient & Sustainable Solutions

Offers tool reconditioning and optimized designs that reduce material waste and extend tool lifespan,

supporting both cost savings and sustainability.

Reliable Long-Term Partnership

Known for dependable service, competitive pricing, and scalable solutions—making MFI a trusted

partner for both short-term projects and ongoing tooling programs.